The industrial world and societies are interdependent, forming an ecosystem where social, environmental, and economic growth must unite. ECM Group enables a decarbonized production of components, materials, or fuels necessary for sectors working towards achieving carbon neutrality.

In this article, we’ll look at how the ECM Group manages to develop and support industries and all its stakeholders in a process of decarbonization and sustainability. In this context, ECM Group aligns with several Sustainable Development Goals (SDGs), with a focus here on objectives related to environmental impact.

For example, we are shareholders in Carbon-Solar, a French company developing an ambitious project to set up a gigafactory in France to produce photovoltaic panels for the European market.

New mobility : electric vehicles :

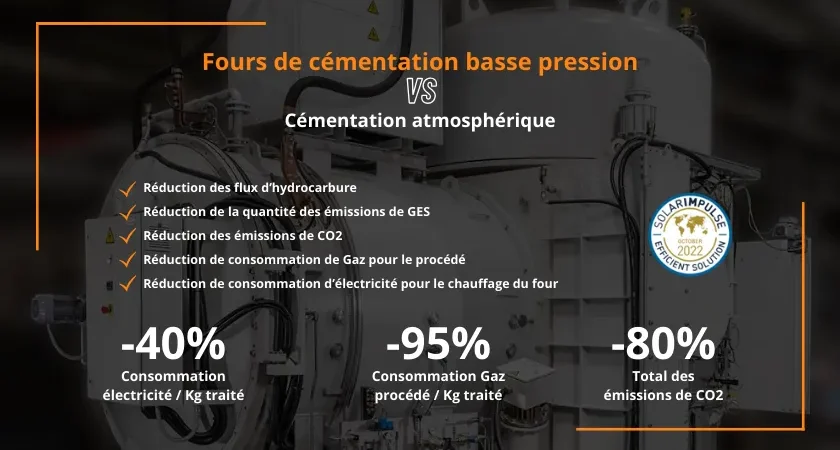

ECM Group, notably through its patented low-pressure carburizing process infracarb® from its subsidiary ECM Technologies, contributes to the development and production efficiency of electric vehicle manufacturers. Low-pressure carburizing is a heat treatment which is also less harmful to the environment than atmospheric carburizing. ECM can supply the process, the equipment and all additional services (installation, training, after-sales service, etc.).

The process is particularly well-suited to meet the high torque requirements of electric vehicles. Our offering also includes turnkey solutions for autonomous and robotized production cells.

Recycling of permanent magnets :

The extraction of rare earths represents a significant environmental challenge, due to the increasing use of these resources in permanent magnet manufacturing. Permanent magnets are directly linked to growing sectors, notably electric vehicle manufacturing and wind turbines.

In this context, ECM Group contributes to several permanent magnet recycling development projects, including the PerMaReco (Permanent Magnet Recovery) project, which brings together a consortium of several companies: PORAL, ARELEC, and ECM Technologies. This project aims to establish a pilot plant for recycling permanent magnets.

For these projects, ECM Technologies acts as a provider of technology and expertise, using advanced processes (hydriding, grinding, powder compaction, and sintering) and its expertise in temperature and vacuum control.

Reducing industrial carbon emissions through our processes and products :

Through innovation, the ECM Group has been able to differentiate itself and offer solutions (processes and equipment) that have less impact on the environment, allowing its industrial clients to significantly reduce their CO2 and greenhouse gas (GHG) emissions.

In this way, ECM Group strongly contributes to the ecological transition of industries, achieving carbon impact reductions of up to 80%. ECM Technologies’ ICBP furnaces, including ECO, Jumbo, Flex, and Nano models, reduce CO2 emissions by up to 80% during production. These furnaces are equipped with electric heating elements and vacuum technology, reducing their carbon footprint compared with traditional gas-heated furnaces.

Here is an infographic comparing ICBP furnaces to atmospheric carburizing furnaces:

Maximizing the lifecycle of our products :

The Retrofit System :

Aware of planetary limits and in order to support our clients in their sustainability plans, our business model encourages reuse and circularity. We can give a second life to equipment and materials that our clients no longer need.

Instead of replacing an entire piece of equipment with a brand-new machine, we offer retrofitting services to extend the life of equipment and installations at our clients’ facilities. This avoids producing a new piece of equipment while modernizing the installation, so even older systems can benefit from innovative and more efficient processes.

Ecodesign, maintainability, repairability and retrofitting are the cornerstones of our development. Some of ECM Technologies’ equipment has been in production for over 40 years, and the gradual adoption of innovations proposed over the years still meets today’s most demanding technical standards.

Reducing the economic impact for the customer, reducing the carbon impact for all stakeholders, reconciling industry, ecology and the economy is a win-win operation.

Our perspectives on the ecological and energy transition (EET) :

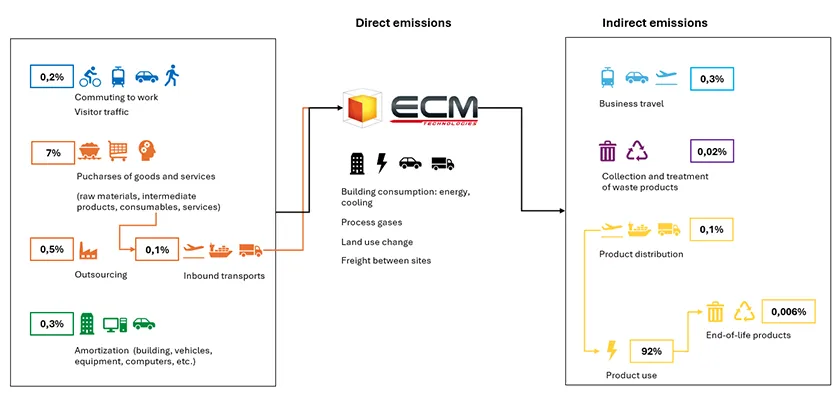

To fully engage in an ecological and energy transition approach, we must first understand our environmental impact and its precise sources.

Here is a diagram showing the carbon footprint of the ECM Technologies subsidiary :

In our industrial group, it is through innovation, cooperation with our ecosystem and our values that we improve the performance and sustainability of our solutions to meet the challenges of our industrial customers.

We invest heavily in innovation (around 10% of sales), with R&I (research and innovation) centers in North America, Europe and Asia.

Our sustainability roadmap is based on a foundation that includes:

- Reducing energy consumption and emissions at client sites

- Innovations in processes and equipment for better energy and environmental efficiency

- Training our teams in eco-design, lifecycle analysis, reuse, and modernization

- Promoting responsible purchasing

- Strong cooperation with our upstream and downstream sectors, as well as supporting the functionality economy within the sector

Engaging our suppliers in a CSR approach :

At ECM, we place corporate social responsibility (CSR) at the heart of our strategy. Our sustainability principles are incorporated into the improvement plans of our various services and activities. They are an integral part of our operational objectives and contribute to our performance indicators within our integrated management system (ISO 9001 – ISO 14001).

Our suppliers are committed to adhering to our CSR charter, just as we do with our own clients. We aim to involve the entire supply chain in a just transition, serving a decarbonized and socially responsible industry.